In Fall and Winter 2020/21 I completed a contract to develop a suite of applications for a manufacturing company. It was a small team and I reported directly to a VP and worked with the floor manager to define requirements. The work was primarily remote with a half a dozen visits to the office for requirement elicitation and production integration. The nature of the small team meant that my project was almost entirely self-supervised.

Phase 1: Requirements Definition #

I met with the team and they showed me around the manufacturing floor and gave me a high level overview of what they needed out of the project. They had a label printer and barcode scanners. They needed automated label printing for each unit manufactured (thousands per month). Units would be scanned as they were stacked on their shipping pallets. Logs would be kept for each pallet with their contents. Ideally automated shipping labels would be created that listed the contents of each pallet. The primary application interface for the floor staff should be scanning labels with a barcode scanner. To minimize risk we decided to prioritize getting a minimum viable product (MVP) ready for a test run so that we could prioritize efforts efficiently.

Phase 2: Analysis of Prior Work #

They had a previous engineer who had worked on this project but it was incomplete and had never been integrated into their production workflow. I dove into their codebase. It consisted of a few Python apps with most of the code being GUI code using Qt for Python. It used MS Access hosted on a network drive as a database. I decided to stay away from the GUI code for the beginning and get the logic set up. The data models were good so I used them. He had worked with their Excel guy to automate a macro to convert their job spreadsheets to CSV files that made it easy to read in the required jobs into the database. This code was solid so I incorporated it.

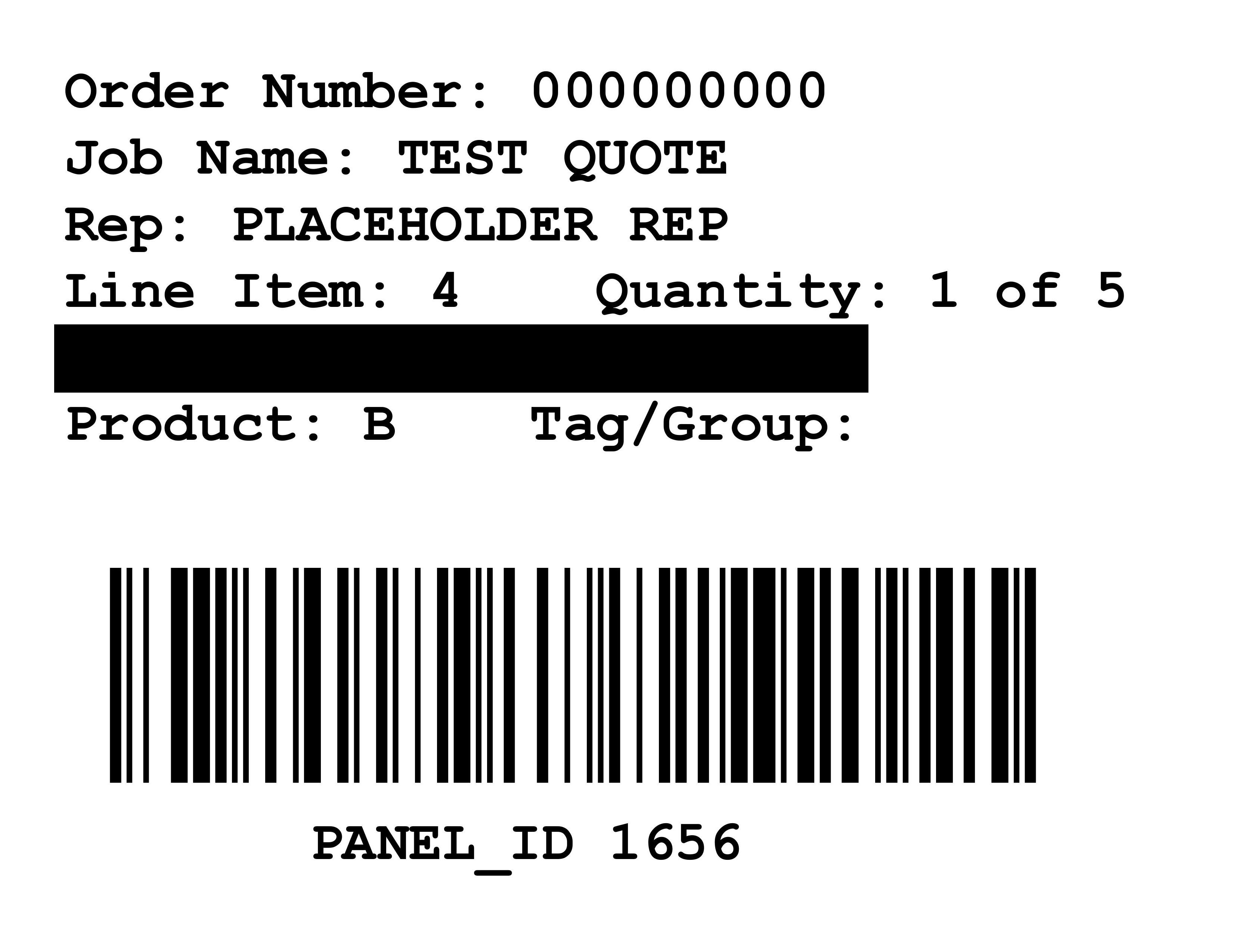

Phase 3: Label Generation #

The biggest uncertainty for me at the beginning of the project was automating the generation of the labels. It turned out they had tried using ZebraDesigner Pro which connected to the MS Access database to generate labels. But the software key cost $345 per computer and they had misplaced their access key. So I researched alternatives and determined that Reportlab Open-Source could be used to minimize their cost and remove the headache of obtaining and setting up expensive license keys for any computer that needed to print labels. Thanks to Lorenzo Simonassi for sharing this Reportlab code snippet which didn't require much tweaking for the final label generation process.

I coded up a quick text-based user interface (TUI) to select from scheduled jobs. From there the user could specify all labels for a job, a single label, or all labels for a series of line items. The program then queried the database for the required data then a PDF containing all of the labels would be generated and opened using the Python code: os.system("start " + LOCAL_LABELS_FILE). The user then reviews and initiates the print from their PDF client.

Later on I engineered a solution to dynamically decrease the label font size in the case of long text fields to ensure that all text is displayed on each label. This was easy to do using the behavior of Frame.add() defined here which returns 0 if the flowable to be added does not fit, and 1 if the draw was successful. In this case we simply define a label generating function generate_label_with_font_size(self, font_size, canvas, label_data) that takes in a font size and returns False in the case of any failed add() and True otherwise. A wrapper function begins with the baseline font size of your choice and decrements the font size until generate_label_with_font_size() succeeds.

def generate_label(self, canvas, label_data):

font_size = 14

while font_size > 0:

if self.generate_label_with_font_size(font_size, canvas, label_data):

break

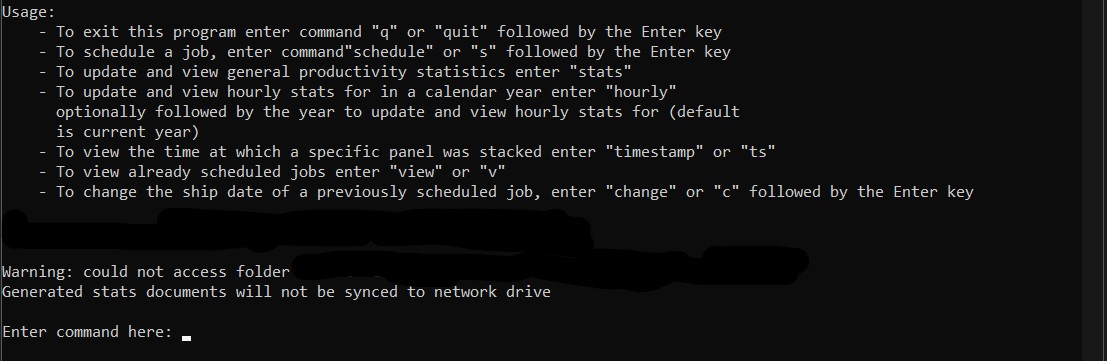

font_size -= 1Phase 4: Job Scheduler #

I forwent the incomplete GUI that had been implemented previously for a simple TUI again in the interest of time. All the scheduler UI had to do was get the job-to-be-scheduled's CSV file and have the user specify the ship date for the job. So a simple drag-and-drop of the CSV file from MS Windows' File Explorer to the TUI pasted the full file-path to the program's stdin. Then the program would prompt the user for the job's ship date. I was able to use prior code to insert the job data into the database.

Phase 5: MS Access Issues #

During Phase 4 I noticed that MS Access did not support concurrent writes. I did some quick searching and learned that MS Access was not recommended for production workflows. It struggles with concurrent accesses and network hiccups. It is also prone to corruption. Even an infrequent number of database issues could be a huge headache in the future.

So I migrated the database schema to an MS Azure-managed PostgreSQL instance and updated the database adapter code to use psycopg. This worked much better.

Phase 6: Scanner Application #

The barcode scanner hardware simply writes to stdout by default. So I coded up another simple TUI to read in the barcode labels sent to stdin by the scanner. For the MVP I decided not to develop a full-on GUI, and provide audio user feedback for successful vs unsuccessful actions.

To define user interface actions, I used MS Word to create printable barcode documents per this. To assign a unit to a pallet, the user scans the pallet's barcode then the unit being stacked. To unassign, the user scans a barcode labeled as "Unassign Unit" followed by the unit's barcode. To create a new label for a new shipping pallet, the user scans the "New Pallet" barcode followed by a panel belonging to the same job as the new pallet.

The program would emit a failure beep upon defined warnings/errors including: database connection errors, double-assignment of a unit and assignment of a unit to a pallet belonging to a different job. It would emit a success beep upon successful assignment of a unit to a pallet.

Phase 7: Scanner Application Additions #

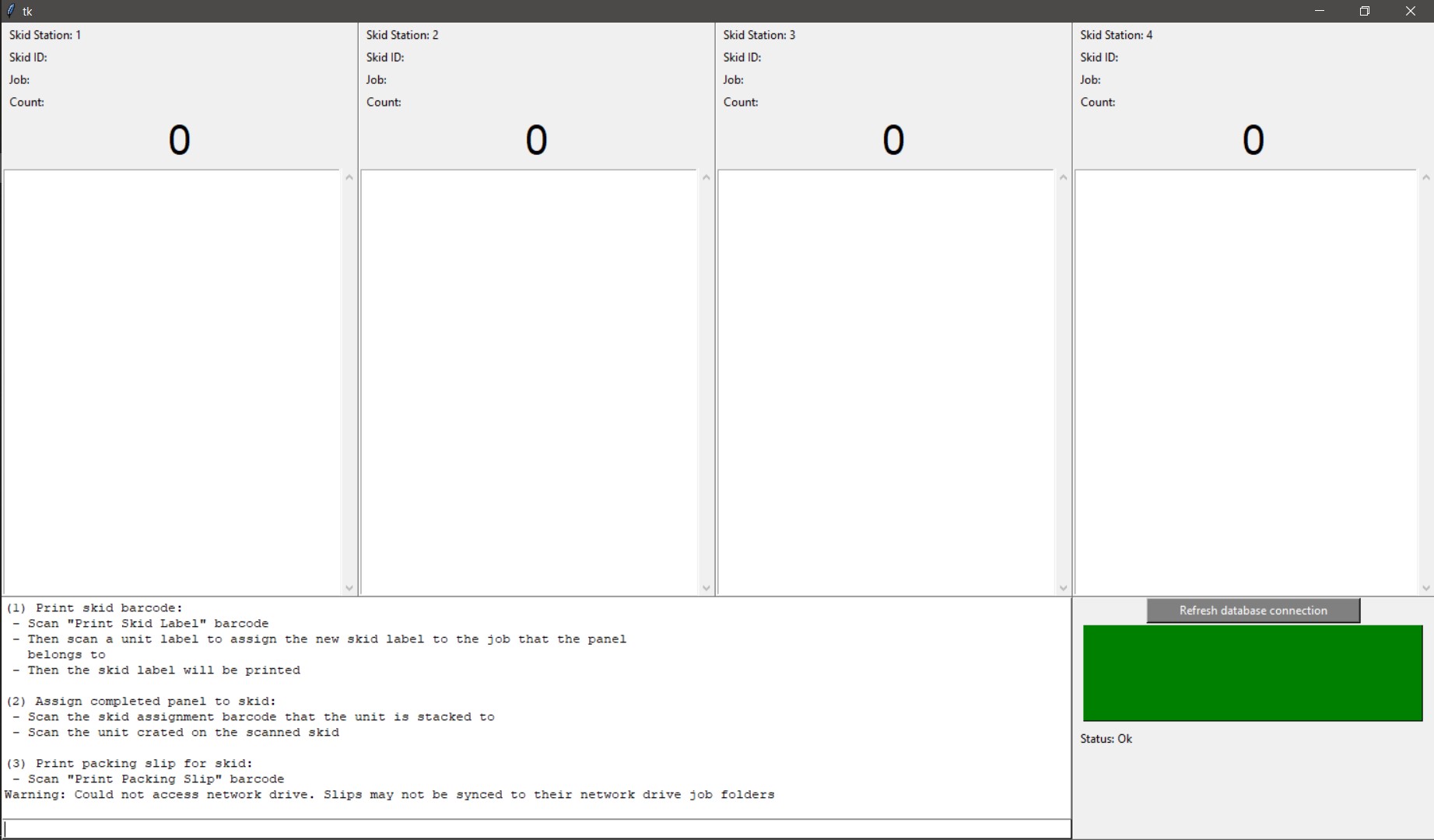

We quickly determined that it was worth the effort for me to develop a GUI to display pallet contents and job info. This would help the floor workers keep track of pallet contents to minimize costly missed scans.

Furthermore, I implemented automatic packing slip printing which listed job information and pallet contents. The information was pulled from the database and then the program uses openpyxl to populate an Excel template. When a job was marked as complete, a master list would be printed listing all units in the job and which pallet they were stacked on. The scanner app initiated the print job without a user needing to use the computer to navigate the Windows print menu using the following code which sent the file to the computer's default printer:

win32api.ShellExecute (

0,

"print",

filename,

'/d:"%s"' % win32print.GetDefaultPrinter (),

".",

0

)The GUI was implemented with Tkinter. It used a simple grid layout with 4 columns one for each pallet . It kept a log of the scanning actions at the bottom. It used a simple colored square to indicate application status with the color green indicating error-free and the color red indicating an error with an error-message below. Pallet unit counts were emphasized in large bold font at the top of each column with the hope that workers could use that to minimize missed scans. The GUI was displayed on a large television above the stacking station.

I then incorporated production statistic generation functionality into the admin app. This broke down the number of stacked units broken down by hour, day and month with an hourly stacking rate for each.

Phase 8: Integration and Bug-Fixes #

I used PyInstaller to bundle the apps together into a single EXE file. This was pretty straightforward, except for the apps requiring ReportLab for which hidden imports needed to be specified for each ReportLab submodule.

The biggest problem initially was the network reliability on the computer running the scanner app. It was connected via WiFi and periodic network disconnects were common. This would break the database connection in the scanner app. I coded up an error message for the network issue and placed a button on the GUI to attempt a database reconnect. They also hardwired the network connection via ethernet which reduced network disconnects drastically.

Another issue that came up was lost labels. During the manufacturing process, a unit would occasionally lose its label. We could determine which job and line item the unit belonged to but we didn't know the unit's ID value for reprint of its label. So I had to create workaround code in the scanner app logic to flag for unit count disparities rather than expecting each unit ID to be accounted for.

Lessons and Takeaways #

Network is unreliable: Accounting for network disconnects in my code was not something I had thought of beforehand but it proved to be essential.

UI is essential: Having pallet contents listed on the television in real-time and clearly visible to those stacking the units allowed the workers to keep track of what they were doing and minimize misscans.

Patience and persistence: The beginning of joining an existing team was quite challenging as I had to catch up to the common conception of the project space. It was important to be patient and trust that with each working hour researching the project space, I was making effective progress towards the end goals even if I wasn't writing code in the beginning.

Vocabulary importance:

When jumping into a new team and project, vocabulary definition is one of the first steps in understanding the project and being able to communicate with the team. The team used jargon that I was not familiar with and so I had to ask many clarification questions in the beginning. The team members had minimal experience managing custom software and so I had to be careful to translate my considerations to outcomes that were tangible to them rather than try to communicate implementation details that would be troublesome to effectively communicate.

If I were a part of a larger organization with significant onboarding scale, I think it would be useful to have documentation of vocabulary and processes for training and reference.

Remote work communication:

Being the only team member working remotely is not easy. It was a small team and each member had a large number of responsibilities. In the beginning I would send long emails asking questions. Responses were understandably inconsistent.

It was not until after diving into the previous code and orienting myself to the organization's documents and workflows by exploring their network drive that I was able to formulate my questions well and get the needed information from an efficient hour and a half team meeting. Had I been working in the office it would have been easier to ask more questions as I went which may have sped up the process.

Experience translates:

My Python experience was limited to small projects for undergrad Security and Web Systems courses. But this baseline proficiency was complimented by my stronger C++ and JavaScript experience which gave me reference points for design patterns and in understanding and searching for tool-specific features.

I had never worked as a contractor or in manufacturing. But my education served me well. I had more than enough experience working as a part of a team to recognize and fulfill my roles both as a teammate and as an individual implementing the project myself.

What I'd Do Differently #

Effort estimation is a notorious challenge in software development. In hindsight I would have doubled my workload estimates. In the beginning of the project I fell behind my predicted milestone timeline. This was a result of overestimating the functionality of the previous engineer's work. I would be better served had I been cynical about the state of the untested code.

Overall, I consider this project to have been efficiently and effectively implemented. The MVP approach worked well as we were able to get an MVP ready for testing quickly. Subsequent testing gave us a much better conception of which additional features to prioritize.

Published